Description

Key Features:

- Material Options:

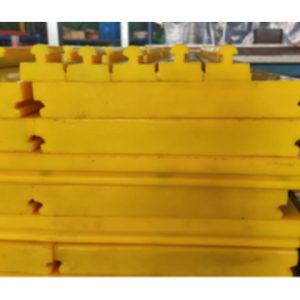

- Rubber: Durable and flexible for various applications.

- Silicone: Softer, ideal for delicate mesh sizes.

- Polyurethane: Highly abrasion-resistant, suitable for harsh conditions.

- Bouncing Action: Dislodges particles to keep the screen clear.

- Self-Cleaning: Maintains optimal material flow and screen efficiency.

- Durability: Built to withstand harsh vibrating conditions.

Functions:

- Prevent Clogging and Blinding: Reduces material build-up on the screen.

- Improve Efficiency: Enhances material separation and throughput.

- Extend Equipment Life: Reduces stress on the screen panels, increasing longevity.

Advantages:

- Enhanced Material Flow: Ensures smoother processing.

- Versatile: Available in different sizes, materials, and hardness levels.

- Reduced Maintenance: Cuts down on cleaning and replacements.

- Cost-Effective: Low-cost solution with high performance.

- Durability: Long-lasting, even in harsh environments.

Applications:

- Mining & Quarrying: For ores, gravel, sand, etc.

- Construction: Sorting aggregates and cement.

- Recycling: Sorting waste materials.

- Industrial Processing: For chemicals, fertilizers, and food-grade products.

Customization:

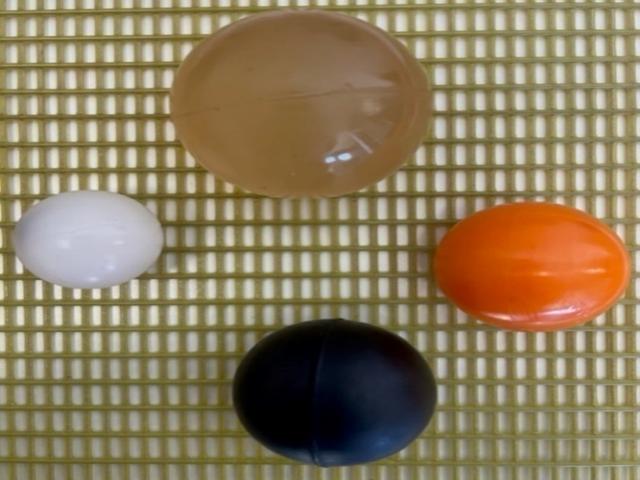

- Material: Rubber, silicone, or polyurethane.

- Size and Hardness: Various diameters and hardness levels.

- Color: Easy identification and tracking.

MMC produces Rubber, Silicone, and Poly Balls in various sizes, tailored to meet your specific needs.