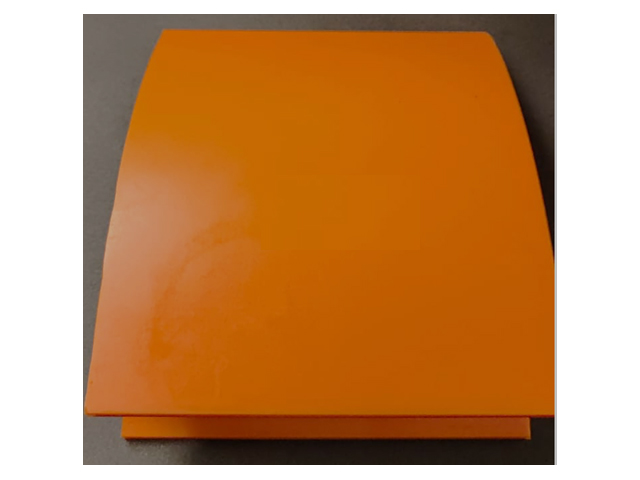

Description

Why Polyurethane Scrapers?

Durability: Polyurethane is highly resistant to wear, making it ideal for tough industrial applications.

Effective Material Removal: Its ability to scrape off attached materials like ash, powder, and fine particles helps maintain clean and smooth-running conveyor systems.

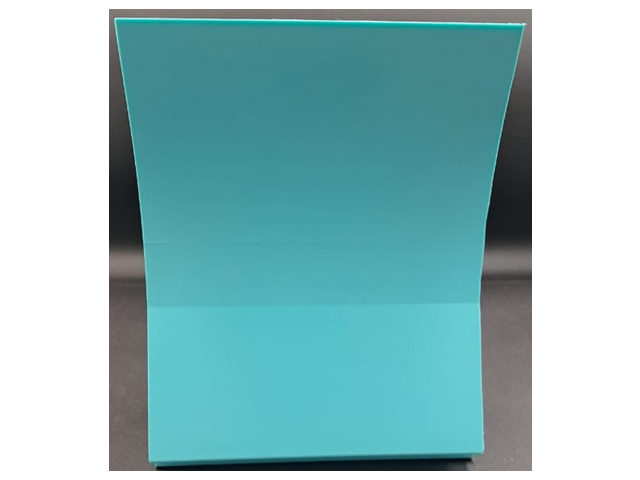

Gentle on Belts: Polyurethane scrapers offer effective cleaning without damaging the belts, especially important for delicate or high-strength belts like steel cord belts.

These scrapers contribute to the overall efficiency and longevity of conveyor systems in harsh environments

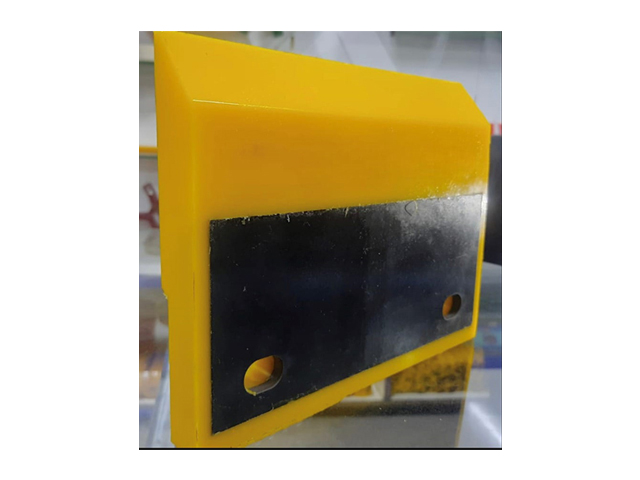

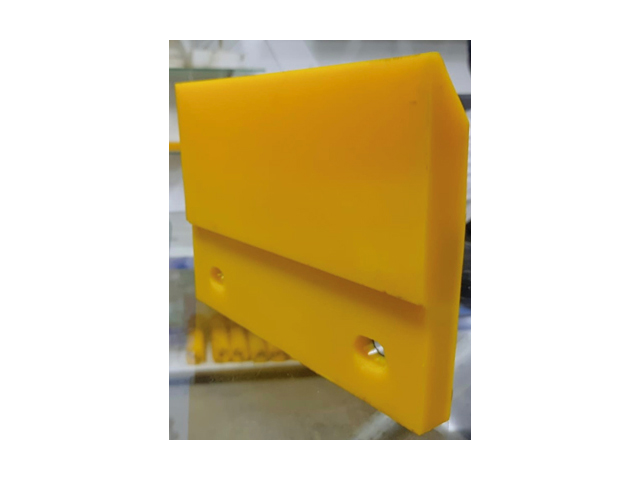

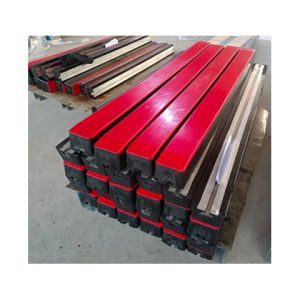

- Primary Belt Cleaners: These are installed at the head pulley to remove large amounts of material from the belt immediately after it exits the conveyor.

- Secondary Belt Cleaners: These are installed further down the belt to remove any remaining material that the primary cleaner missed.

- Tertiary Belt Cleaners: Often used in more specific applications or when cleaner belts are needed for sensitive operations.

- RBC (Reverse Blade Cleaners): These use reverse blade technology to clean the underside of the conveyor belt.

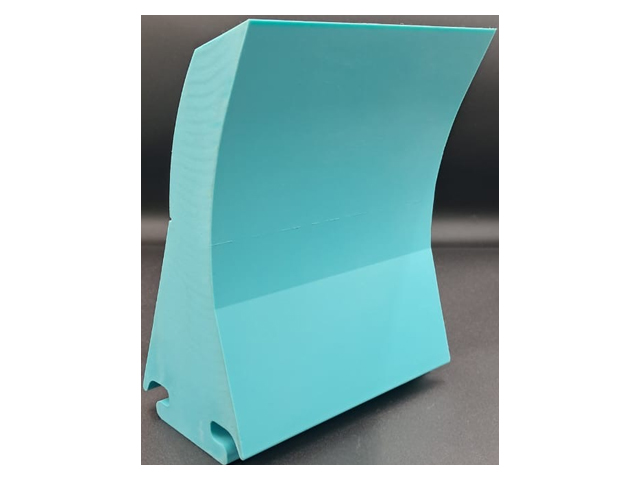

- V Plough: Used to remove material that has spilled onto the belt from the conveyor system, preventing buildup and improving overall efficiency.

Key Features:

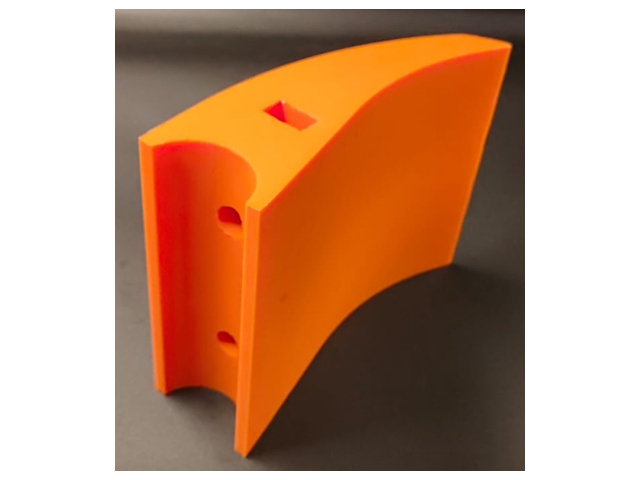

- Higher Strength: Designed to be robust enough to clean effectively without causing damage, particularly important for steel cord belts.

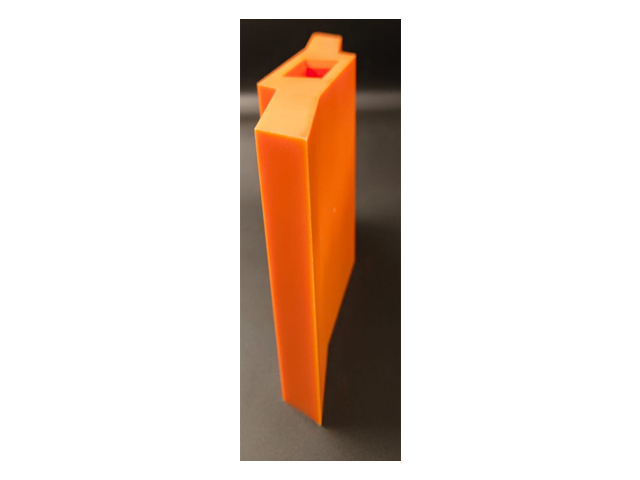

- Flexibility and Stiffness: Adaptable to different belt profiles to ensure proper cleaning across various conveyor setups.

- Low Friction Coefficient: This reduces wear and tear on the belt and cleaner itself, improving longevity.

- Fire Retardant & Anti-Static Properties: Especially valuable for applications in industries like mining where safety standards require extra precautions against fire hazards and static electricity.

- Pre-Slotted Mounting Holes: These make installation faster and easier, reducing downtime and the risk of injury during setup.

This combination of features helps ensure that your conveyor system runs efficiently, with minimal maintenance or downtime.

Application:

Polyurethane scraper is commonly used in coal chemical conveyor belts for scraping off the attached ash and powder material. Such as the coal transportation, fertilizer transport, gravel transport and many other applications