Description

Key Features:

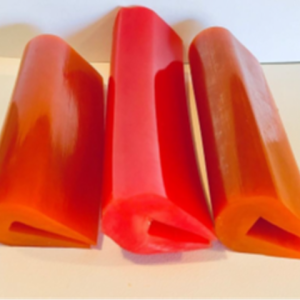

- Elastic Polyurethane Construction: Durable, flexible, and vibration resistant.

- Self-Cleaning: Moves with screen vibration to shake off sticky particles.

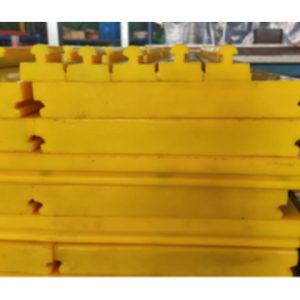

- Modular Design: Can be connected (Modular design) to cover the entire screen.

- Easy Installation: Simple to set up with minimal effort.

- Customizable Configurations: Fits various screen sizes and setups.

Primary Functions:

- Prevent Pegging & Blinding: Eliminates blockages and improves screening efficiency.

- Enhance Material Flow: Keeps screen areas clear for consistent throughput.

- Extend Screen Life: Reduces wear by minimizing material buildup.

- Improve Productivity: Reduces downtime for manual cleaning.

Advantages:

- Increased Efficiency: Prevents material buildup, keeping screens clear.

- Reduced Maintenance Costs: Less frequent cleaning and replacement needed.

- Durable & Long-Lasting: Resistant to wear, impact, and chemicals.

- Versatile: Suitable for various materials, including sticky and abrasive substances.

- Eco-Friendly: Reduces waste and need for cleaning chemicals.

Applications:

- Mining and Quarrying: For screening ore, coal, and gravel.

- Aggregate Processing: Ideal for sand, stone, and construction materials.

- Industrial Screening: Works in fertilizer, chemical, and food plants.

- Recycling: Helps in sorting plastics, metals, and glass.

Customization Options:

- Rod Length & Thickness: Various sizes to fit different screens.

- Connection Types: Flexible configurations for screen coverage.

- Material Grades: Options for UV-stabilized or chemical-resistant polyurethane.

- Color Coding: Custom colors for easy identification.