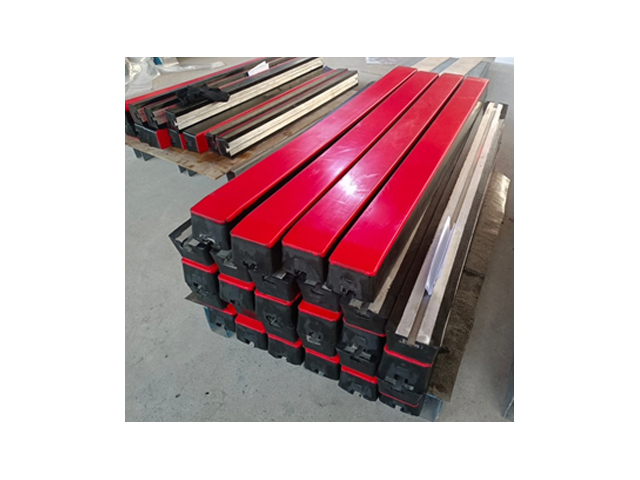

Description

Key Features of our Impact Bars:

- Abrasion Resistance:

- The abrasion resistance of impact bars is a critical factor in ensuring the longevity of both the bars and the conveyor system. These bars are made from high-quality materials specifically designed to withstand wear and tear from constant material impact. The abrasion-resistant materials prevent premature degradation, ensuring that the bars maintain their effectiveness over time and are able to handle high-load conditions without significant wear.

- UHMWPE (Ultra High Molecular Weight Polyethylene), often used in the top layer of the impact bar, is renowned for its exceptional resistance to abrasion. This ensures that the bars remain operational for a longer period, reducing the frequency of replacements and minimizing downtime.

- Aluminium T-Track Profile:

- The aluminium T-track profile integrated into the impact bar allows for quick and easy installation onto the conveyor system. This user-friendly design ensures that the bars can be securely fastened to the conveyor frame with minimal effort, improving the overall efficiency of installation and replacement. The aluminium profile also adds strength and durability to the bars, helping them withstand operational stress while maintaining their structural integrity.

- This feature also makes the impact bars highly adaptable to different conveyor configurations, allowing for customization based on system requirements.

- Shock Absorbing Rubber:

- The impact bars incorporate a shock-absorbing rubber layer, which plays a critical role in absorbing the impact forces generated during material handling. This rubber layer cushions the impact between the material and the conveyor system, preventing direct damage to the conveyor belt and supporting structure.

- The rubber helps distribute the shock load more evenly across the surface, reducing the likelihood of localized wear and tear, which can cause premature failure in other conveyor components. It also contributes to reducing noise and vibration, making the operation smoother.

- UHMWPE Top Layer:

- The top layer of the impact bar is made from Ultra High Molecular Weight Polyethylene (UHMWPE), a material known for its superior durability and resistance to abrasion. UHMWPE is one of the toughest materials available, offering a smooth, slippery surface that allows for easy material flow and reduces friction between the impact bar and the conveyor belt.

- This top layer enhances the performance of the impact bar by significantly extending its service life and ensuring that the conveyor system continues to operate smoothly under heavy-duty conditions. The UHMWPE layer also contributes to the bar’s ability to resist the buildup of material, further reducing wear and the need for maintenance.

Stocked Sizes:

We offer a range of conveyor impact bars in various sizes to suit different conveyor system requirements. The following sizes are commonly stocked:

- 55mm x 100mm x 1250mm

- 55mm x 100mm x 1500mm

- 75mm x 100mm x 1250mm

Additionally, T bolts are available for securing the impact bars to the conveyor system, ensuring reliable installation and a secure fit.

Benefits of Using Impact Bars:

- Enhanced Durability:

- Impact bars made from abrasion-resistant materials like UHMWPE and rubber provide long-lasting performance, reducing the need for frequent replacements. This contributes to a more cost-effective and efficient conveyor system.

- Protection for Conveyor Belts:

- By absorbing shocks and distributing impact forces, impact bars prevent damage to conveyor belts and other sensitive parts of the conveyor system, helping to maintain the integrity of the overall system.

- Reduced Maintenance Costs:

- The shock-absorbing properties of the impact bars help to minimize wear on the conveyor system, reducing the frequency and cost of repairs. They help keep operational downtime to a minimum and reduce the need for costly belt replacements.

- Improved System Efficiency:

- The ability of impact bars to absorb and distribute shocks ensures smoother operation, reducing belt slippage, misalignment, and other performance issues. This contributes to the overall efficiency of the conveyor system, making it more reliable and productive.

- Versatility:

- Impact bars are available in different sizes and configurations to accommodate various conveyor designs. Their adaptability makes them suitable for a wide range of industries, including mining, manufacturing, material handling, and more.

- Easy Installation and Maintenance:

- The aluminium T-track profile and shock-absorbing rubber layer make installation and maintenance simpler and more efficient. The system can be quickly installed, and impact bars can be easily replaced when necessary, reducing downtime and operational disruption.

Applications of Impact Bars:

- Conveyor Systems: For protecting belts and frames at loading points, transfer chutes, and other areas with high material impact.

- Mining: Used in bulk handling operations, where materials like coal, minerals, or aggregates can cause heavy impacts.

- Material Handling: In industries dealing with heavy loads or high-throughput systems, where shock and vibration are common.

- Cement and Quarrying: Where heavy and abrasive materials like gravel, limestone, and sand are conveyed.