Description

Key Features of our Rubber Magnetic Patches:

- Magnetic Strength: The embedded magnets in the rubber patches provide a strong, secure bond to metal surfaces, ensuring that the patches stay in place even in high-stress or high-vibration environments. This makes them ideal for applications such as chutes, hoppers, and conveyor systems.

- Durable Rubber Construction: Made from high-quality rubber compounds, these patches are designed to be wear-resistant, flexible, and able to withstand harsh environments. The rubber provides additional protection against abrasion, impacts, and extreme temperatures, enhancing the longevity of the equipment they are applied to.

- Easy Installation: The magnetic nature of these patches allows for quick and tool-free installation. Simply position the patch on a clean, metal surface, and the magnets will secure it in place. This simplicity reduces downtime and minimizes labor costs.

- Versatile Applications: Rubber magnetic patches are used across various industries, including mining, construction, and manufacturing. They are commonly applied to chutes, hoppers, conveyor belts, deflector plates, and other material handling equipment to protect against wear, abrasion, and corrosion.

- Surface Protection: The rubber layer on the magnetic patch protects the underlying metal surfaces from damage caused by friction and impact from bulk materials. This not only extends the lifespan of the equipment but also reduces the frequency of repairs and replacements.

- Resistant to Harsh Conditions: Rubber magnetic patches are built to withstand tough environmental conditions such as exposure to high temperatures, moisture, chemicals, and UV radiation. This resilience makes them suitable for both indoor and outdoor applications.

- Reusability: One of the key advantages of rubber magnetic patches is that they are reusable. Once the patch is worn or damaged, it can be removed, inspected, and reattached as needed, offering an economical and sustainable solution.

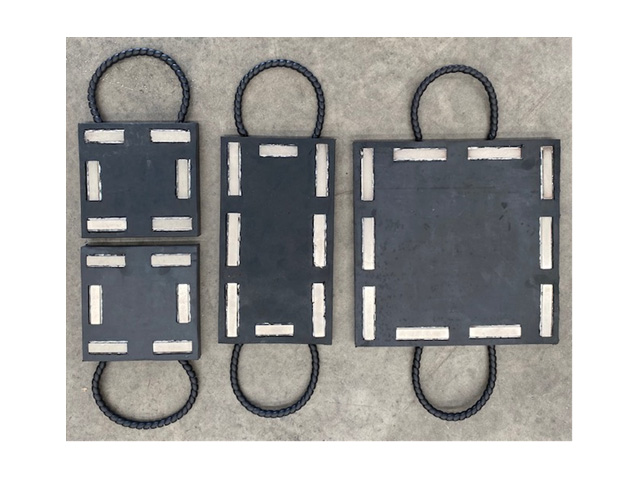

- Customizable Sizes and Shapes: Rubber magnetic patches can be manufactured in a variety of sizes and shapes to fit specific applications. Custom designs can be produced based on the client’s needs, allowing for optimal fit and function.

Benefits of Rubber Magnetic Patches:

- Cost-Effective: With a longer service life and the ability to be reused, these patches reduce maintenance and replacement costs.

- Timesaving: Their easy installation and removal process significantly reduce downtime, allowing for more efficient operations.

- Enhanced Equipment Longevity: Protecting critical surfaces from wear and tear helps extend the lifespan of the machinery and equipment, leading to better overall productivity.

- Safety: The secure attachment of the patches helps prevent slipping, shifting, or detachment of materials, contributing to safer working conditions.

- Reduced Maintenance: As the patches protect critical surfaces from wear, maintenance requirements are minimized, reducing the need for regular servicing.

Applications of Rubber Magnetic Patches:

- Material Handling: Used in conveyor systems, chutes, hoppers, and bins to prevent damage from abrasive materials, improving the longevity of the equipment.

- Mining and Aggregate Processing: Applied to deflector plates, crushers, and screens in the mining industry to protect against the abrasive nature of mined materials.

- Automotive and Industrial Equipment: Rubber magnetic patches are used on machinery and production lines to protect parts from wear, particularly in heavy machinery operations.

- Construction: Used on construction equipment like bulldozers, trucks, and machinery that deal with heavy and abrasive materials.

By combining the durability of rubber with magnetic functionality, rubber magnetic patches offer a reliable, cost-effective, and versatile solution for surface protection and material handling in many industries.

- 20 x 165 x 165mm

- 20 x 165 x 300mm

- 20 x 300 x 300mm

**CAN BE CUSTOMISED TO ANY THICKNESS AND SIZES