Description

Brush Applications:

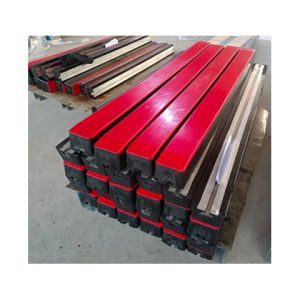

Metal Backed Brushes:

Heavy-Duty Use: These brushes are ideal for applications requiring more robustness, such as industrial cleaning, heavy material removal, or high-pressure environments.

Synthetic Backed Brushes:

Lightweight & Dense: These brushes are particularly useful in industries where precision and cleanliness are critical.

Industries:

Food Industry: Where hygiene is a top priority, these brushes help maintain cleanliness without contaminating products.

Glass Industry: Soft synthetic filaments help clean delicate surfaces without scratching.

Printing Industry: Soft or hard filaments can be used for specific tasks like cleaning printing rollers or handling fine materials.

Fitting & Supply Options:

Direct Mounting: Brushes can be supplied mounted directly onto shafts.

Refillable Cores: For easier maintenance and replacement, they can be supplied with refillable cores.

Loose Brushes: Spiral wound brushes can be supplied loose for installation onto existing shafts, providing flexibility for a variety of setups.

Filament Options:

Filament Hardness: Depending on the application, customers can choose from soft to hard brush filaments, adjusting the brush’s flexibility and cleaning power.

Customization: The ability to adjust brush density, flexibility, and filament hardness makes spiral wound roller brushes highly adaptable for a wide range of applications.

Durability & Resistance: Metal-backed brushes offer strength for heavy-duty tasks, while synthetic-backed brushes provide lightweight, precise cleaning without damaging surfaces.

Hygiene & Efficiency: Synthetic-backed brushes are particularly beneficial for industries where cleanliness and food safety are priorities.

A full range of filaments are available. All synthetic fibres from .005” (0.13mm) to 0.180” (3.0mm).

All types of hairs, natural fibres, abrasives, and wires available.